LEADING THE SECTOR

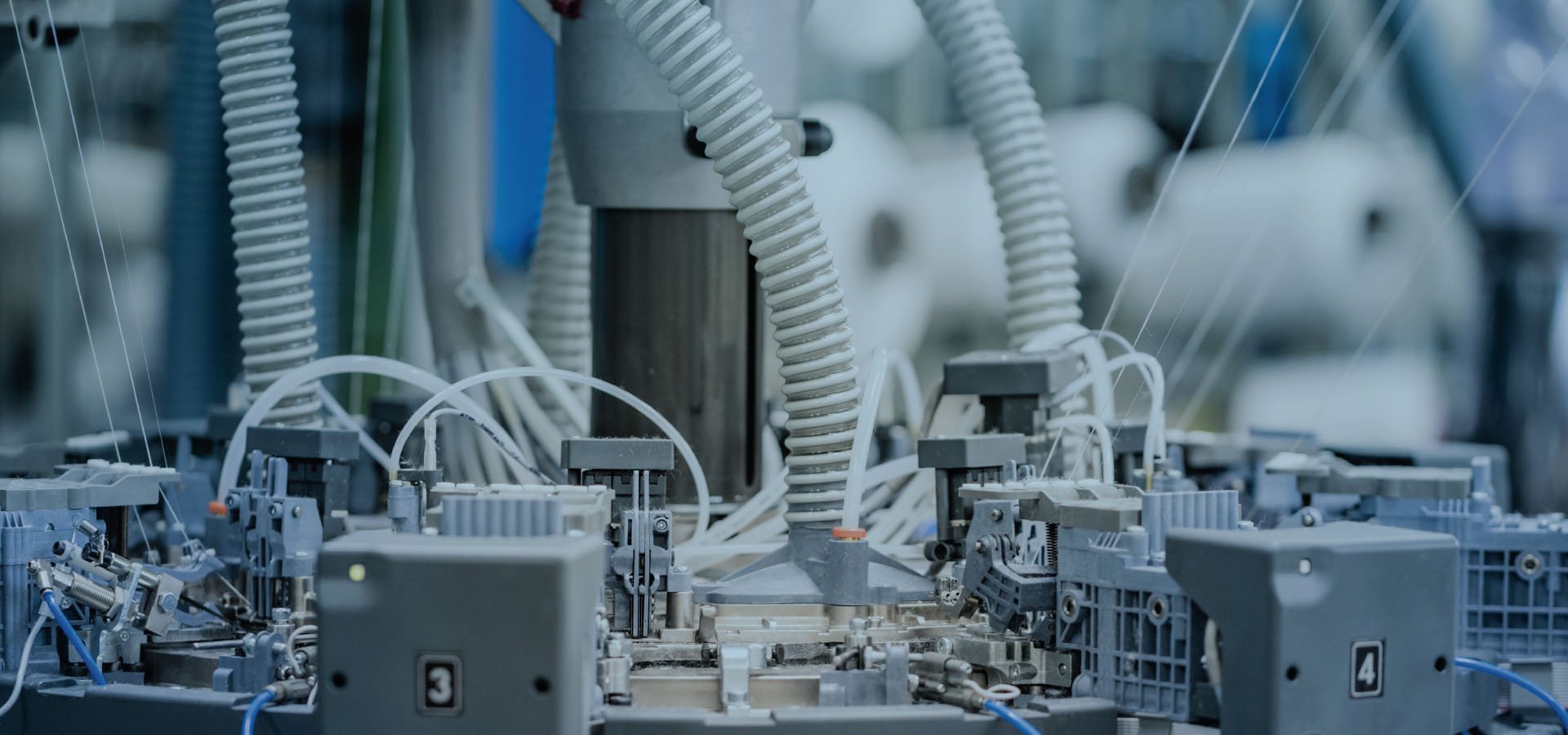

The Lonati Group’s machines cover almost the entire world production of women’s hosiery, 60 per cent of men’s and children’s hosiery, 90 per cent of sportswear and seamless production and 60 per cent of traditional knitwear production. Thanks to the acquisition of historic national and international brands, the development and optimisation of technologies, and its worldwide expansion, the Lonati Group has taken local industrial traditions to unprecedented levels. The whole Group takes its strength and inspiration from these origins.

A CONSTANT PASSION: INNOVATION.

A world leader for hosiery machinery, with annual production of more than 8,000 machines, LONATI can boast the largest assortment of plants for men’s, women’s and children’s hosiery to which the footwear sector was added in 2018 with the production of circular machines for shoe uppers. Lonati implements environmentally friendly technologies and strict protocols to protect the environment, an essential strategic goal also for efficient process management, increased company value and customer satisfaction. The IMS is certified by the UNI EN ISO 9001/2015 and ISO 45001/2018 certifications, plus the ISO 8001 Green Label Certification for certain types of products.

The first Italian company to produce hosiery machines, Santoni was established in 1919 and joined the Lonati Group in 1989. Thanks to a Tiberio Lonati intuition, SANTONI is the leader in the production of electronic circular machines for seamless garments and meets 97% of the worldwide demand for seamlesswear machines for the different clothing sectors: underwear, sportswear, beachwear, outerwear and medicalwear, up to the recent conquest of the knitted outerwear sector. The footwear sector was added in 2018, with the production of circular machines for shoe uppers. The company has an in-house training centre, the SANTONI SCHOOL, aimed at educating technicians and operators on hardware and software technology.

Thanks to its constant and painstaking technological research, TECNOPEA has achieved the highest quality in the production of automatic boarding and packaging machines for men, women and children’s hosiery. The company’s dynamic management and automation degree guarantee efficient and fast customer service worldwide.

RENOWNED INDSUTRIAL COMPANIES

Established in 1982, VIGNONI immediately became one of the most important manufacturers of circular knitting machines; over the years, the undeniable distinctiveness of its design allowed it to make a name for itself through the high quality and reliability of its products. In 1998, the company was taken over by SANTONI. Currently, single and double knitting machines are manufactured under the VIGNONI brand for the production of “basic” items, plain and fancy jersey or brushed fabric, terry, minijack and electronic jacquard, as well as traditional interlock and rib knits.

A leading manufacturer of circular knitting machines for men and children’s socks for over 50 years. SANGIACOMO offers a large selection of products: single-cylinder machines with Classic Linking toe-closing device and circular machines for the production of seamless underwear, nightwear, outerwear, swimwear and sportswear.

The company was established in 1974 and joined the ENI group in 1978. Since its beginning, MATEC has successfully worked in Italy and abroad as one of the technological and market leaders. MATEC subsequently was taken over by Parmec and then sold to the Lonati Group. Currently, the MATEC brand is used for the production of machines for women’s tights, single-cylinder machines for men’s socks and machines for the medical line.

Thanks to over 60 years of experience, MEC-MOR is the brand dedicated to the marketing and brokerage of electronic circular and straight textile machines for open and closed panel knitwear.

K-Fabric is the Lonati Group’s revolutionary new process aimed at changing the way fabrics are created with straight machines, saving space, time and costs. K- Fabric is based on the Lonati Group’s circular machine technology and transforms circular fabric into linear fabric, with significant advantages for customers in both fabric quality and cost-effective terms. A product that represents both an innovation for the textile sector and an opportunity for stylistic and technological renewal. A new approach to “circular weaving”, a new fabric, which represents the new production paradigm par excellence, in order to adapt both to the expected growth in high-end production demand and to the changes going on in supply chain models and search for new materials.